Cerex Air Sentry FTIR

Optical, remote sensing, sub parts-per-billion (ppb) to percent level gas analyzer

The Cerex Air Sentry was the first open path FTIR to be commercialized and has continued to lead the industry with reliable performance and innovative features. It performs chemical detection and quantification of compounds using open-path, Fourier Transform InfraRed (FTIR) Differential Optical Absorption Spectroscopy (DOAS).

It is the recognized choice in open-path FTIR and the most reliable for monitoring industrial facilities, accidental releases, and hazardous waste site emissions.

- Monitors from 1 to 1,000 meters

- Eliminates need for many single point gas-specific sensors

- No lengthy calibrations or time-consuming laboratory analysis

- Deep sensitivity – detects concentration of gases that traditional sensor arrays can’t

Cerex Air Sentry FTIR

Optical, remote sensing, sub parts-per-billion (ppb) to percent level gas analyzer

The Cerex Air Sentry was the first open path FTIR to be commercialized and has continued to lead the industry with reliable performance and innovative features. It performs chemical detection and quantification of compounds using open-path, Fourier Transform InfraRed (FTIR) Differential Optical Absorption Spectroscopy (DOAS).

It is the recognized choice in open-path FTIR and the most reliable for monitoring industrial facilities, accidental releases, and hazardous waste site emissions.

- Monitors from 1 to 1,000 meters

- Eliminates need for many single point gas-specific sensors

- No lengthy calibrations or time-consuming laboratory analysis

- Deep sensitivity – detects concentration of gases that traditional sensor arrays can’t

Air Sentry OP-FTIR (Standard)

Weight 150 lbs (68kg)

Measurements with Telescope 42” x 23″ x 20″ (109cm x 59cm x 51cm)

Enclosure NEMA 4X – IP65, thermoelectrically cooled

Power 10A/6A @ 120/220 VAC

Operating Temperature -40°F – 140°F (-40°C – 60°C)

Optical Path Length 5m – 1000m

A lighter weight, air cooled, version is available for some applications.

Installation

- Suitable for corrosive environment system deployment

- Tripod mountable for semi-permanent installations

We recommend sheltering against wind and solar loading for permanent installations

Maintenance

- Recommend semi-annual inspections of dirt buildup on the exterior heat-sink fins.

- Rinse air conditioner fins as needed

- Fans are rated to 40,000 hours at 40°C

- IR source life time is approximately 2 years

- Stirling cooler (detector cryocooler) guaranteed for 2 years before refurbishment is required

- A maintenance free, thermoelectrically (TE) cooled, detector is available for some applications

Retroreflector

Used to reflect infrared light transmitted by Air Sentry along the original beam bath back to the instrument.

How it Works

Open Path FTIR Technology

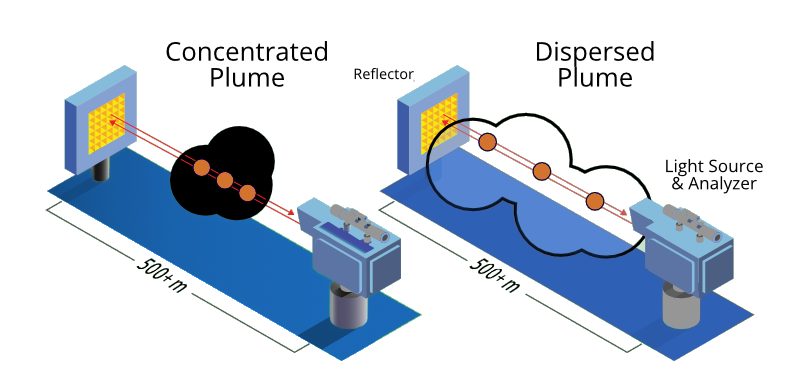

The Cerex AirSentry FTIR operates by sending a beam of Infrared light through the open air. In a mono-static installation, the IR beam is reflected back to the analyzer by a retro-reflector array, where the absorption due to target gases is measured and recorded. The analyzer uses a classical least squares regression analysis to compare the measured absorption spectrum to calibrated reference absorption spectra files per USEPA TO-16 Methodology. Beer’s Law is used to report accurate gas concentrations.

Fourier transform infrared spectroscopy (FTIR) is the preferred technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid, and gas.

The Cerex AirSentry FTIR is the only commercial open-path FTIR evaluated in 2 US EPA site studies and proven capable of detecting, identifying, and quantifying air toxins.

(Above) Process of open-path monitoring (depicted with a Cerex UV Sentry). Similarly, the AirSentry FTIR mounts to a precision pan and tilt head which may be used with a tripod for rapid deployment, or with a fixed mount for permanent installations. The retro-reflector array is housed in a NEMA enclosure and may be tripod or fixed mounted to a mast, pole or superstructure. Monitoring path lengths are typically configured to meet minimum detection limits required for the project. Paths to 1 km are possible. The IR beam is eye-safe and the analyzer may be located directly in the breathing zone. Gases present in the beam path are identified and quantified in near real time. Credit: STI

Common Detectable Gases

Extensive Library with Options for Customization

Cerex has over 385 compounds available for detection with the AirSentry. If your compound is not one of the compounds already available within our database, the Cerex AirSentry FTIR may import gas spectra from the numerous FTIR databases on the web (NIST, EPA, PNNL, etc.)

If you have a compound that is not available in a public database, we may be able to work with you to develop a custom spectrum. Detection limits are a function of the IR detector, installed path length, and site conditions. The detection limits shown have been empirically determined from bump tests of fielded instruments at full path-length.

It is efficient as an alarm and easily integrated into your existing alarm system.

*NOTE: If desired target gases are available within the UV spectrum, we recommend the Cerex UV SENTRY for better pricing options. The UV Sentry is an open-path analyzer that uses UV-DOAS (Ultra Violet Differential Optical Absorption Spectroscopy). Find more information about UV-DOAS and FTIR techniques here.

Air Sentry FTIR Common Target Gases

| Acetaldehyde (C2H4O) |

| Acetic Acid (C2H4O2) |

| Acetone (CH3COCH3) |

| Acetylene (C2H2) |

| Acrolein (C3H4O) |

| Benzaldehyde (C7H6O) |

| Butane (C4H10) |

| n-Butyl (C6H12O2) |

| Carbon Dioxide (CO2) |

| Carbon Monoxide (CO) |

| Chlorine Dioxide (ClO2) |

| Ethane (C2H6) |

| Ethanol (C2H6O) |

| Formaldehyde (CH2O) |

| Formic Acid (CH2O2) |

| n-Hexane (C6H14) |

| Hydrogen Bromide (HBr) |

| Hydrogen Chloride (HCl) |

| Hydrogen Fluoride (HF) |

| Methane (CH4) |

| Nitric Oxide (NO) |

| Nitrogen Dioxide (N2O) |

| Phenol (C6H5OH) |

| Phosgene (CCl2O) |

| Water Vapor (H2O) |

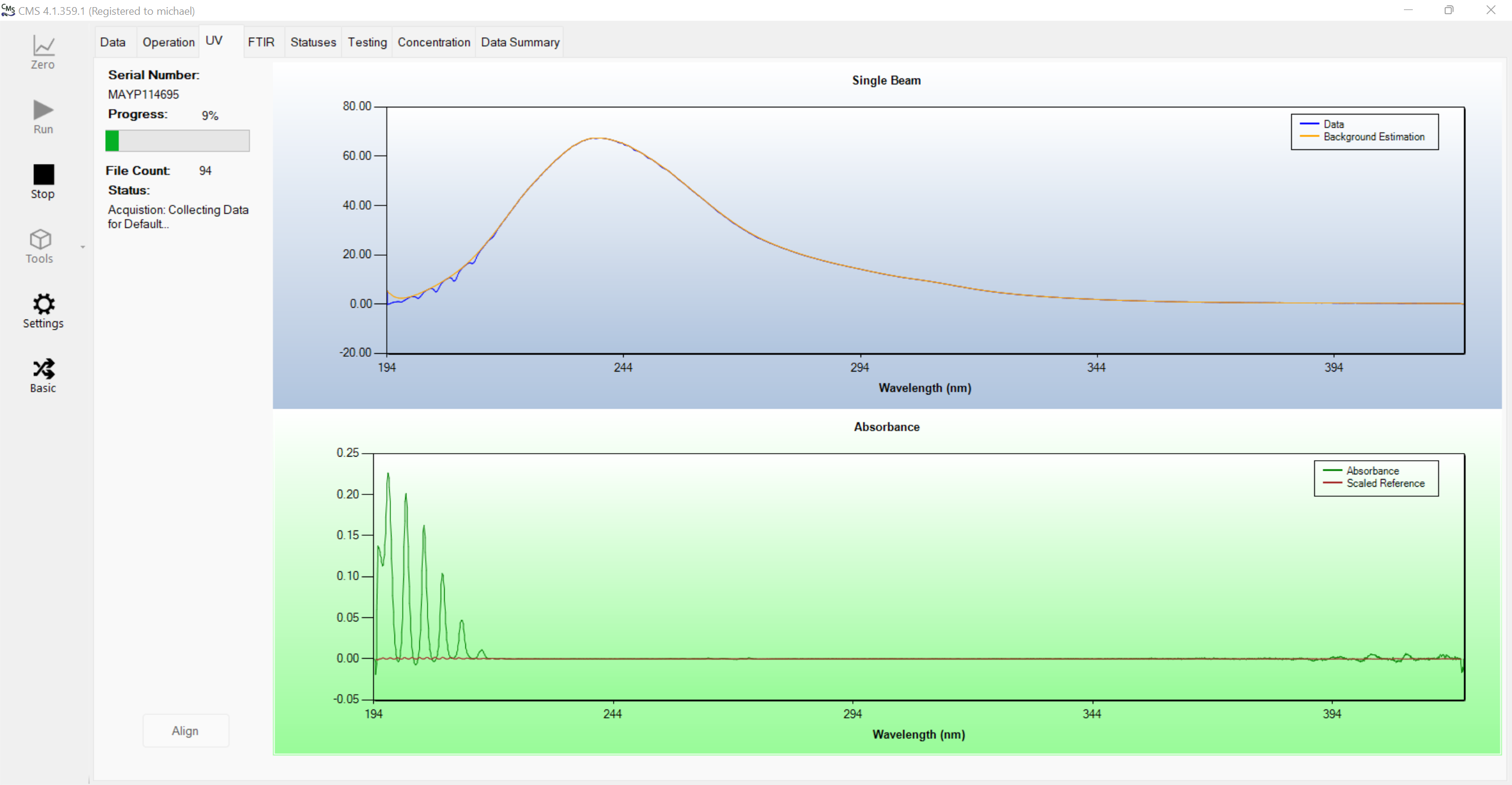

Software

Results You Can Rely On

Cerex recognizes that detailed gas monitoring results need to be reliable and available quickly to various stakeholders. For this reason, Cerex engineers developed software to accurately detect and display gases within the air in real time from any location.

On an Air Sentry FTIR, a user can see results remotely on a phone, tablet, or computer anywhere in the world via a virtual connection. GPS and cellular configurations make this possible in isolated environments.

All data is automatically saved in an easy to access .csv file; this feature helps our clients in various ways - from daily use to crucial events such as evidence in court. Early detection translates into quicker response times, reduced environmental impact, decreased plant downtime, and reduced exposure to site personnel and the community.

Real time spectral subtraction and synthetic background implementation allow the Air Sentry to clearly display accurate concentrations of target gases over 1000 meters without interference from other gas species

Applications

Hundreds of successful installations

In 2019 alone, 190 Air Sentry units were provided to various clients

Cerex has been manufacturing the AirSentry FTIR since 1994 and continues to provide support for these fielded instruments. With hundreds of detectable compounds, the AirSentry FTIR has been utilized as a stand-alone monitoring solution for petrochemical industries, semiconductor plants, agriculture, landfill, and site surveys of historically polluted areas.

With its hundreds of detectable compounds, the AirSentry is the comprehensive choice for fulfilling compliance regulations for varying government proposals, including, but not limited to:

- "The HON" (Hazardous Organic NESHAP) as of 04/06/23

- Rule 1180 and refinery fenceline air monitoring

- US EPA TO-16 Compliant Monitoring (in open path mode)

It may be rapidly converted from open path mode to point analyzer mode with the inclusion of an optional sample cell. In open path mode, the AirSentry FTIR offers full USEPA TO-16 compliant monitoring. In point analyzer mode, the AirSentry FTIR meets a variety of method compliance standards.

All Applications

Acid Plant Monitoring

Brownfield Remediation

Chemical Depot Monitoring

Chemical Manufacturing

Concrete Manufacturing

Electrowinning Emissions Monitoring

Fence-line Monitoring System (FLMS)

Manufactured Gas Plant Remediation (MGP)

Ore Processing

Perimeter Ambient Monitoring System (PAMS)

Refinery Operations and Monitoring

Superfund Site Remediation

Tank Farm Monitoring

Regulation Compliance

"The HON" (Hazardous Organic NESHAP) Rules

Benzene, 1,3-Butadiene, Ethylene Dichloride, Vinyl Chloride, Chloroprene

USEPA Method 318

Extractive FTIR Method for Measurement of Emissions from Mineral Wool and Wool Fiberglass Industries

USEPA Performance Specification 15

Extractive FTIR CEMS in Stationary Sources

USEPA Method 320

Vapor Phase Organic and Inorganic Emissions by FTIR

USEPA Method 321

Determination of HCl for Portland Cement Industries

NIOSH Method 3800

Organic and Inorganic Gases by Extractive FTIR Spectrometry

ASTM Method D6348-03

Determination of Gaseous Compounds by Extractive Direct Interface Fourier Transform Infrared Spectroscopy

Air Sentry Specifications

| Type | Compound | MDL PPB | ||||

| Criteria | Sulfur Dioxide | 300 | ||||

| Volatile Organic Compounds | Acrolein | 15 | ||||

| 1,3 Butadiene | 4 | |||||

| Styrene | 8 | |||||

| BTEX | Benzene | 30 | ||||

| Toluene | 100 | |||||

| Ethylbenzene | 25 | |||||

| m-Xylene | 100 | |||||

| o-Xylene | 300 | |||||

| p-Xylene | 300 | |||||

| Alkanes | Pentane C5 | 4 | ||||

| n-Hexane C6 | 3 | |||||

| TVOC | Methane C1 | 3 | ||||

| NMHC | Ethane C2 | 8 | ||||

| NMNEHC | Butane C4 | 4 | ||||

| Propane C3 | 4 | |||||

| Formaldehyde | 7 | |||||

| Propene (propylene) | 6 | |||||

| Ethene (ethylene) | 4 | |||||

| Acetylene | 4 | |||||

| Acetaldehyde | 5 | |||||

| Methanoic Acid | 5 | |||||

| Methanol | 4 | |||||

| Other | Hydrogen Cyanide | 10 | ||||

| Hydrogen Fluoride | 4 | |||||

| Ammonia | 3 | |||||

| Hydrogen Sulfide | 450 | |||||